CNC Machining Trends: Insights from Top Manufacturers and Suppliers in 2023

In the dynamic landscape of CNC machining, being attuned to the latest innovations is essential for success. At Kansd Precision Industry Co., Ltd., we specialize in delivering custom manufacturing solutions tailored to each project’s unique requirements. Our focus on cutting-edge technology enables us to produce high-quality components that boost productivity and minimize lead times. By choosing us as your supplier, you gain access to our expertise and unwavering commitment to excellence. Collaborate with us to leverage the evolving trends in Cnc Machining Trends, ensuring that your projects not only meet expectations but exceed them. Your success is our priority!

The Clear Choice of Cnc Machining Trends Stands Out Delivers Unmatched Quality

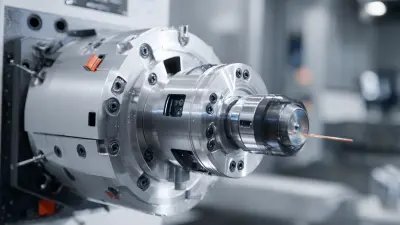

In today’s rapidly evolving manufacturing landscape, Cnc Machining has emerged as a pivotal technology that stands out for its precision and efficiency. The latest trends in Cnc Machining highlight a shift towards automation, sustainability, and advanced materials, offering global buyers unmatched quality and reliability. As industries seek to optimize their production processes, integrating state-of-the-art CNC machines and lathes into manufacturing operations not only elevates product quality but also enhances overall productivity. Moreover, the rise of smart manufacturing is revolutionizing how Cnc Machining operations are conducted. With capabilities such as real-time monitoring and adaptive machining processes, businesses can ensure consistency and precision in production. The combination of advanced grinding machines and medium-speed wire cutting machines further highlights the commitment to precision engineering, allowing for intricate designs and tolerances to be achieved consistently. By embracing these trends, global purchasers can secure a competitive edge, ensuring they meet customer demands with swift turnaround times and exceptional product quality. Ultimately, the clear choice for discerning procurement professionals is to partner with manufacturers that leverage these advanced machining technologies. In a marketplace where excellence is paramount, selecting a supplier that prioritizes innovation and precision will guarantee the exceptional outcomes that today’s industries demand. Investing in this level of quality assurance not only satisfies immediate operational needs but also fosters long-term business growth in an increasingly competitive landscape.

The Clear Choice of CNC Machining Trends Stands Out Delivers Unmatched Quality

| Trend | Description | Impact on Quality | Adoption Rate (%) |

|---|---|---|---|

| Additive Manufacturing | Integration of 3D printing in CNC processes for complex geometries. | Enhances customization and reduces waste. | 45% |

| Automated CNC Systems | Use of robotics and AI to automate the Cnc Machining process. | Improves precision and throughput. | 60% |

| Advanced Materials | Utilization of high-performance materials like composites and titanium. | Increases durability and performance of machined parts. | 50% |

| Digital Twin Technology | Creating a digital replica of physical machining processes for analysis. | Optimizes processes and reduces errors. | 30% |

| Sustainable Practices | Focus on eco-friendly materials and energy-efficient processes. | Improves brand reputation and complies with regulations. | 55% |

Methods To Cnc Machining Trends Manufacturer Outperforms the Competition

M

Michael Sampson

The product quality exceeded my expectations. The support team was incredibly responsive and professional, making the entire experience seamless.

25 June 2025

E

Emma Smith

Quality products coupled with outstanding customer support. The professional approach of the staff left a lasting impression on me.

03 July 2025

J

Jackson Campbell

Exceptional quality product. The staff were knowledgeable and went above and beyond to assist me.

29 May 2025

M

Mia Wright

I’m highly satisfied with my purchase. The quality is superb, and the support team provided unparalleled service.

11 May 2025

D

Daniel Harris

I really appreciate the quality of the product. The support team was prompt and knowledgeable, which made all the difference!

05 June 2025

E

Ella Johnson

Incredible quality! The after-sales team showed a great deal of professionalism and expertise.

12 June 2025