01

How KANSD's Precision Manufacturing is Transforming the Medical Device Landscape

2025-08-06

In the highly specialized and demanding world of medical device manufacturing, precision is not just a preference; it's a necessity. KANSD has emerged as a key player, revolutionizing this landscape through its unparalleled precision manufacturing techniques.

The Imperative of Precision in Medical Devices

Medical devices are the cornerstone of modern healthcare, from life - saving surgical instruments to diagnostic equipment that enables early disease detection. The slightest deviation in the manufacturing process can have dire consequences. For instance, a surgical tool with even a minuscule inaccuracy could potentially lead to unsuccessful procedures, causing harm to patients. This is where KANSD's precision manufacturing comes into play.

KANSD's Precision - Driven Approach

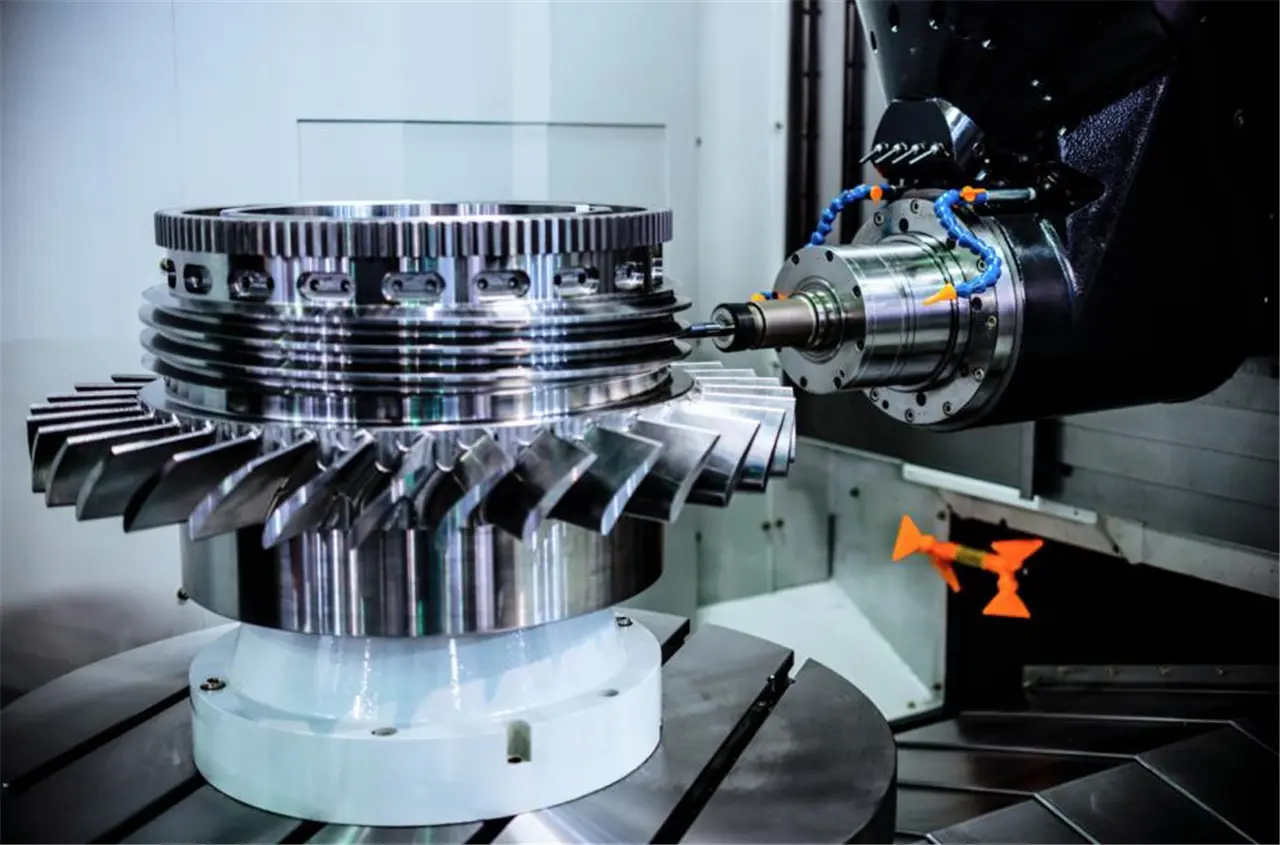

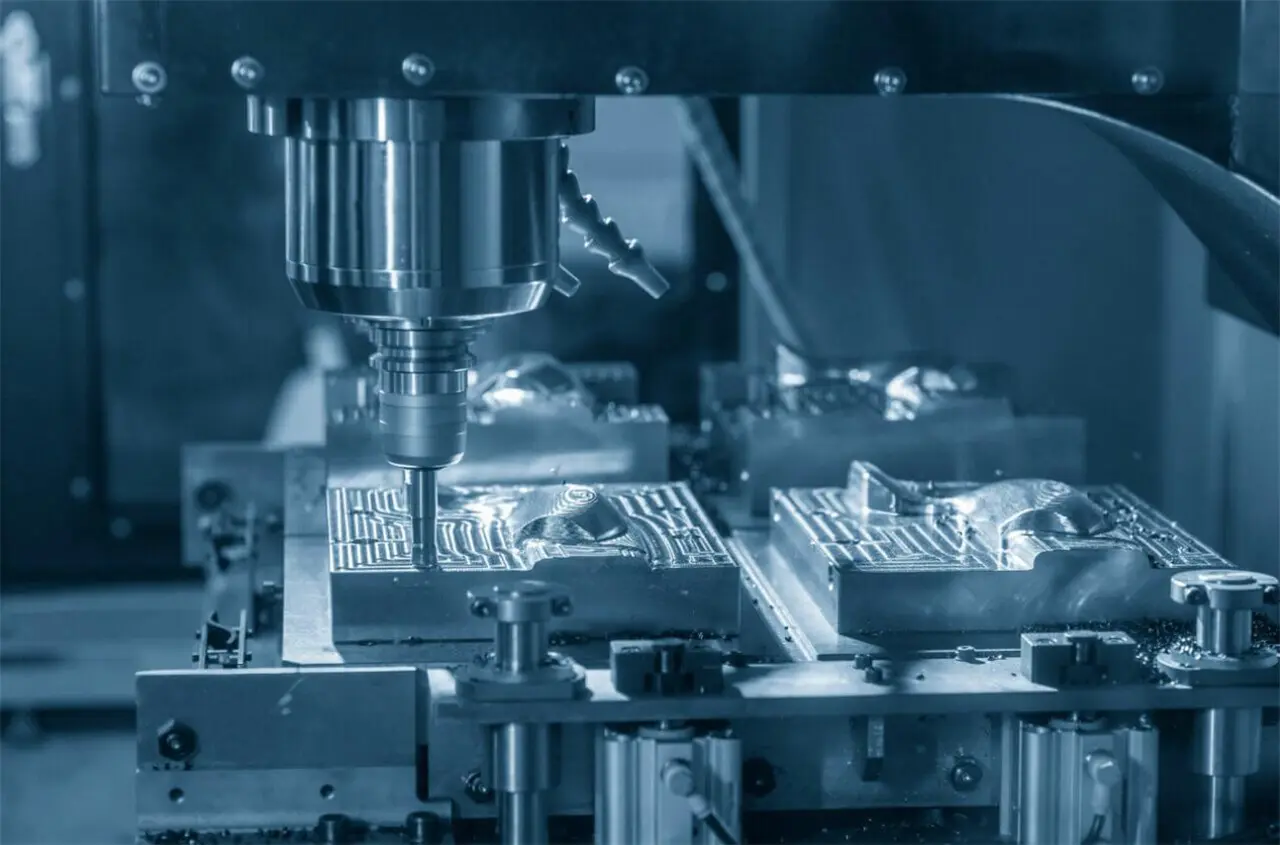

Advanced Equipment at the Core

KANSD is equipped with state - of - the - art machinery. Our CNC machines, for example, are programmed to execute complex designs with an astonishing ±0.002 - millimeter tolerance. This level of precision ensures that every component, whether it's a tiny connector in a diagnostic imaging device or a critical part of a surgical robot, meets the exact specifications required. The use of high - end milling machines, lathes, and grinding equipment further enhances our ability to create components with the utmost accuracy. These machines are regularly calibrated and maintained to guarantee consistent performance, a crucial factor in medical device manufacturing where reliability is non - negotiable.

Skilled Team: The Human Touch

Behind our precision manufacturing is a team of highly skilled professionals. Our engineers and technicians have an average of over 8 years of experience in the precision manufacturing industry. Their in - depth knowledge and expertise allow them to tackle even the most complex design challenges. They work closely with medical device designers, understanding the unique requirements of each project. This collaborative approach ensures that the final product not only meets but often exceeds the expectations of our medical clients. Whether it's developing a new type of catheter with enhanced flexibility and precision or a custom - made implant with a perfect fit, our team's attention to detail is unwavering.

Impact on the Medical Device Industry

Enhanced Performance of Medical Devices

The precision components manufactured by KANSD have led to a significant improvement in the performance of medical devices. In the case of diagnostic equipment, such as MRI machines, our precisely crafted components reduce signal interference, resulting in clearer images. This, in turn, enables doctors to make more accurate diagnoses, potentially saving lives. For surgical instruments, the high - quality and precision - made parts ensure smooth operation, reducing the risk of complications during procedures.

Accelerating Innovation in Medical Technology

KANSD's capabilities have also spurred innovation in the medical technology sector. By providing manufacturers with the ability to produce complex and highly accurate components, we have enabled the development of new and improved medical devices. For example, the creation of minimally invasive surgical tools has been made possible due to our precision manufacturing techniques. These tools allow for less invasive procedures, shorter recovery times for patients, and ultimately, a better quality of life.

Quality Assurance: The Bedrock of Our Medical Offerings

We understand that in the medical field, quality cannot be compromised. That's why KANSD is ISO 9001 and ISO 13485 certified. Our in - house metrology lab is equipped with top - of - the - line equipment, including coordinate measuring machines (CMMs), optical comparators, and surface roughness testers. These tools are used to conduct rigorous inspections at every stage of the manufacturing process, from raw material incoming inspection to final product testing. This comprehensive quality control system ensures that the defect rate of our medical components is kept as low as 0.4%, guaranteeing that only the highest - quality products reach our medical clients.

In conclusion, KANSD's precision manufacturing is indeed transforming the medical device landscape. By combining advanced equipment, a skilled team, and a commitment to quality, we are enabling the development of safer, more effective, and innovative medical devices. As the healthcare industry continues to evolve, KANSD is poised to remain at the forefront, driving further advancements through our precision manufacturing expertise.